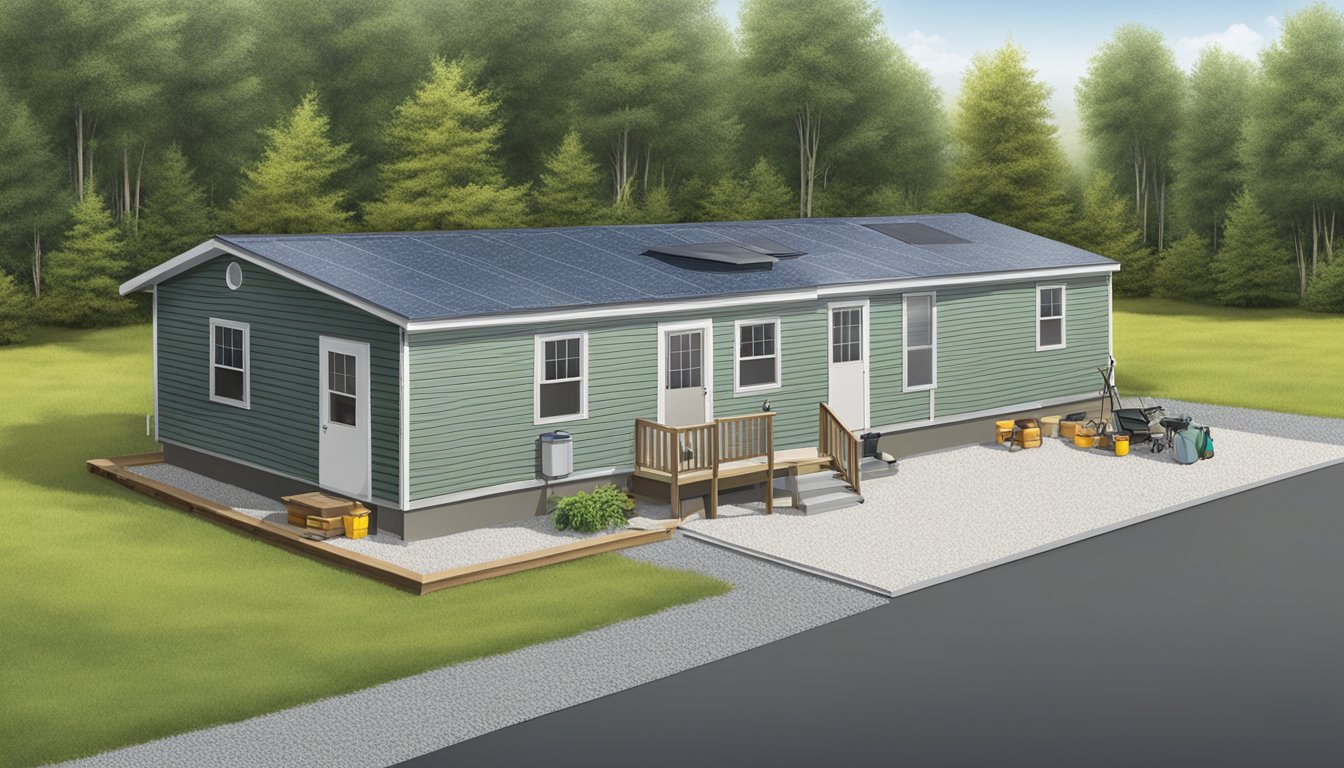

Mobile home pad requirements are crucial for ensuring the stability and safety of manufactured homes. These specifications dictate the foundation upon which a mobile home is placed, providing a secure base for the structure.

Mobile home pads typically need to be level, properly graded for drainage, and constructed of materials like concrete or compacted gravel. The exact requirements can vary depending on local building codes, soil conditions, and the specific type of mobile home being installed.

Proper pad preparation is essential for preventing issues like settling, shifting, and water damage. It also plays a key role in anchoring the home and meeting tie-down regulations that protect against high winds and other environmental forces. Homeowners and installers should always consult local authorities and professional engineers to ensure compliance with all applicable standards for mobile home pad construction.

Understanding Mobile Home Foundations

Mobile home foundations provide crucial support and stability for manufactured housing units. They come in various types designed to meet different needs and regulations.

Different Types of Foundations

Pier and beam foundations are common for mobile homes. They consist of concrete piers or wooden posts supporting the home’s frame. Slab foundations offer a solid concrete base, providing excellent stability and moisture protection.

Crawl space foundations elevate the home slightly, allowing access underneath for maintenance. Basement foundations provide additional living space but are less common due to higher costs.

Each foundation type has unique advantages. Pier and beam foundations are cost-effective and allow for easy leveling adjustments. Slab foundations offer superior protection against pests and moisture. Crawl spaces facilitate easier access to plumbing and electrical systems.

Permanent vs Non-Permanent Foundations

Permanent foundations are designed for long-term stability and often required for financing or zoning compliance. They typically involve concrete footings, anchors, or full perimeter walls. These foundations enhance the home’s value and durability.

Non-permanent foundations, such as basic pier systems, offer more flexibility for relocation. However, they may not meet local building codes or mortgage requirements.

Permanent foundations provide better protection against wind and seismic forces. They also reduce the risk of settling and shifting over time. Non-permanent options are generally less expensive but may limit the home’s resale potential.

Foundation Stability and Safety

Proper foundation design is crucial for mobile home safety. Factors like soil type, climate, and local building codes influence foundation requirements. Regular inspections help identify issues like settling, cracks, or moisture problems.

Anchoring systems are essential for stability, especially in areas prone to high winds or earthquakes. These systems secure the home to the foundation, preventing uplift and lateral movement.

Proper drainage around the foundation is critical to prevent water damage and soil erosion. Gutters, grading, and waterproofing measures help protect the foundation’s integrity. Insulation and skirting around the foundation can improve energy efficiency and aesthetics.

Site Preparation for Mobile Home Pads

Proper site preparation is crucial for ensuring the stability and longevity of a mobile home pad. This process involves assessing and modifying the soil, as well as managing compaction and topsoil.

Soil Assessment and Modification

Soil assessment is the first step in site preparation. A professional should evaluate the soil type and composition. Clay soils may require additional drainage measures, while sandy soils might need reinforcement.

If the existing soil is unsuitable, it may need to be excavated and replaced with more appropriate materials. This often involves adding a layer of gravel or crushed stone to improve drainage and stability.

The site should be graded to ensure proper water runoff. A slight slope away from the home’s foundation is recommended, typically 5-6 inches over the first 10 feet around the home.

Compaction and Topsoil Management

Proper soil compaction is essential for creating a stable foundation. The soil should be compacted in layers using heavy machinery to achieve the required density.

A compaction test may be necessary to ensure the soil meets the required bearing capacity for the mobile home’s weight.

Topsoil management is crucial for preventing erosion and maintaining proper drainage. After compaction, a layer of topsoil should be added and graded to match the surrounding landscape.

This topsoil layer helps with water absorption and provides a base for future landscaping. It’s important to maintain a balance between proper drainage and soil retention to prevent erosion around the pad.

Design and Construction of Mobile Home Pads

Mobile home pads serve as the crucial foundation for manufactured homes. Proper design and construction ensure stability, durability, and compliance with local building codes. Two common approaches are concrete pads and pit and runner foundations.

Concrete Pad Specifications

Concrete pads provide a solid, level surface for mobile homes. The pad should be at least 4 inches thick and reinforced with wire mesh or rebar. Its dimensions must exceed the home’s footprint by 2-3 feet on all sides.

The concrete should have a minimum compressive strength of 3,000 psi. Proper site preparation involves removing topsoil and vegetation, then compacting the subgrade. A layer of gravel helps with drainage.

The pad’s surface must be smooth and level, with a slight slope for water runoff. Anchor points for tie-downs are typically embedded in the concrete during pouring.

Pit and Runner Foundation Details

Pit and runner foundations combine excavation with concrete or treated lumber supports. The pit is typically 12-18 inches deep, filled with gravel for drainage.

Runners are parallel beams that support the home’s chassis. For concrete runners, they should be 16-24 inches wide and 8-12 inches thick. Treated lumber runners must be rated for ground contact.

Proper spacing of runners is crucial. They should align with the home’s frame rails, typically 8-10 feet apart. Cross-bracing between runners adds stability.

Piers are placed on the runners to support the home. These can be concrete blocks or adjustable metal stands. Proper leveling and load distribution are essential.

Compliance with Building Codes and Regulations

Mobile home pad construction must adhere to strict building codes and regulations at multiple levels of government. These standards ensure safety, structural integrity, and proper installation of manufactured homes.

Local and State Regulations

Local jurisdictions and state governments often have specific requirements for mobile home pads. These may include zoning laws, setback requirements, and construction standards. Some areas mandate concrete pads, while others allow gravel or compacted soil. Pad size and thickness specifications vary based on local soil conditions and home dimensions.

Many states require licensed contractors to install manufactured homes. Inspections are typically necessary at various stages of pad preparation and home installation. Permits are usually required before work can begin.

Federal Manufactured Home Standards

The U.S. Department of Housing and Urban Development (HUD) sets national standards for manufactured home construction and installation. HUD’s Model Manufactured Home Installation Standards provide guidelines for foundation systems, including:

- Proper site preparation

- Drainage requirements

- Vapor barrier installation

- Pier placement and spacing

- Anchoring systems

These federal standards work in conjunction with state and local regulations. Manufacturers must design homes to meet HUD standards, while installers must follow both federal and local requirements when preparing pads and setting homes.

Installation and Contractor Selection

Proper installation is crucial for the safety and longevity of a manufactured home. Selecting the right contractor and following best practices ensures a secure and compliant setup.

Choosing a Qualified Contractor

Licensed and experienced contractors are essential for manufactured home installation. Look for professionals certified by the state or industry organizations. Check their references and past projects.

Ask potential contractors about their familiarity with local building codes and HUD standards. Inquire about their insurance coverage and warranties.

Request detailed quotes from multiple contractors. Compare their timelines, materials, and methods. Be wary of unusually low bids, as they may indicate subpar work or hidden costs.

Best Practices for Installation

The installation process begins with proper site preparation. Ensure the pad is level and compacted to support the home’s weight. Implement effective drainage to prevent water accumulation.

Follow manufacturer guidelines for anchoring systems. Use approved tie-downs and ensure they’re properly tensioned. Install vapor barriers to protect against moisture.

Carefully connect utilities according to local codes. Proper setup of plumbing, electrical, and HVAC systems is critical for safety and functionality.

Conduct a thorough inspection after installation. Address any issues promptly. Obtain necessary permits and schedule official inspections to ensure compliance with all regulations.

Maintenance and Repair of Mobile Home Pads

Proper upkeep of mobile home pads is crucial for the stability and longevity of the structure. Regular maintenance prevents major issues, while timely repairs address damage and ensure a solid foundation.

Routine Maintenance Tips

Inspect the pad regularly for signs of wear or damage. Check for cracks, settling, or erosion around the edges. Clear debris and vegetation from the pad’s surface and surrounding areas.

Ensure proper drainage by maintaining a slight slope away from the home. Clean gutters and downspouts to prevent water accumulation near the pad.

Apply a sealant to concrete pads every 2-3 years to protect against moisture penetration. For gravel pads, add fresh gravel as needed to maintain an even surface.

Keep the area under the mobile home dry and well-ventilated. Install a vapor barrier if moisture is a persistent issue.

Repair Strategies

Address small cracks in concrete pads promptly with epoxy or polyurethane injections. For larger cracks or uneven settling, consider mud jacking or slab jacking techniques.

Repair erosion damage by adding compacted soil and installing proper drainage solutions. Use retaining walls or French drains if necessary to prevent future erosion.

Replace damaged sections of asphalt pads with new material, ensuring proper compaction and sealing. For gravel pads, regrade and add new gravel to restore a level surface.

If significant damage occurs, consult a professional to assess the need for pad replacement or reinforcement. Structural repairs may require permits and should comply with local building codes.